We are a premier provider of operation and maintenance services for Sewage Treatment Plants (STPs). With years of experience and a dedicated team of experts, we specialize in ensuring the smooth functioning and optimal performance of STPs based on various technologies including STP based on MBBR, STP based on SBR, STP based on MBR, STP based on Extended Aeration across various sectors and industries. Our commitment to excellence and sustainable solutions makes us the preferred choice for all your STP operation and maintenance needs.

MGF and ACF are commonly used acronyms in the context of water treatment plants (WTP). Here’s what they stand for:

MGF: Multi-Grade Filter A Multi-Grade Filter (MGF) is a type of filtration system used in water treatment. It typically consists of multiple layers of granular media, such as anthracite coal, silica sand, and garnet, with varying particle sizes. The MGF is designed to remove suspended solids, turbidity, and some finer particles from water. The larger particles get trapped in the upper layers, while the finer particles are captured in the lower layers, ensuring effective filtration.

ACF: Activated Carbon Filter An Activated Carbon Filter (ACF) is a filtration system that utilizes activated carbon as the filter media. Activated carbon is a highly porous material with a large surface area, which allows it to adsorb organic compounds, chemicals, taste and odor compounds, and some dissolved contaminants from water. ACFs are commonly used for the removal of residual disinfectants (e.g., chlorine), volatile organic compounds (VOCs), pesticides, and other organic contaminants.

Both MGF and ACF are important components of water treatment plants, often employed as part of the treatment train to ensure the removal of different types of impurities and improve the overall quality of treated water. The selection and use of MGFs and ACFs depend on the specific water quality requirements and the contaminants present in the water source.

Water softener are used to treat hard water by reducing its mineral content, primarily calcium and magnesium ions. Hard water is characterized by high concentrations of these minerals, which can cause various issues such as scale buildup, soap scum, and reduced effectiveness of soaps and detergents.

Water softener consists of a mineral tank filled with a specific type of resin known as ion exchange resin. The resin beads are charged with sodium ions. When hard water passes through the resin bed, the calcium and magnesium ions in the water are attracted to the resin, and in exchange, the resin releases sodium ions into the water.

The process of ion exchange effectively removes the hardness minerals from the water, leaving it “soft.” Periodically, the resin bed becomes saturated with calcium and magnesium ions, and the water softener initiates a regeneration cycle. During regeneration, a concentrated salt solution (brine) is flushed through the resin, causing the exchange of sodium ions with the calcium and magnesium ions. The excess minerals and salt solution are then rinsed away, leaving the resin bed recharged and ready for the next cycle.

Water softeners offer several benefits:

Scale prevention: By removing the hardness minerals, water softeners help prevent the buildup of scale in pipes, appliances (such as water heaters and dishwashers), and plumbing fixtures. This can prolong the lifespan of these components and improve their efficiency.

Improved cleaning: Soft water lathers more easily with soaps and detergents, leading to better cleaning results. It also helps reduce soap scum and improves the effectiveness of personal care products like shampoos and soaps.

Energy efficiency: Soft water can improve the efficiency of water heating systems, as there is less scale accumulation on heating elements. This can result in energy savings and lower utility bills.

Extended lifespan of appliances: By reducing scale buildup, water softeners can help prolong the life of appliances that come into contact with water, such as washing machines, coffee makers, and dishwashers.

Softer skin and hair: Soft water is gentler on the skin and hair, as it rinses away more easily and doesn’t leave a residue. This can result in smoother skin, reduced dryness, and shinier hair.

It’s important to note that while water softeners are effective in reducing hardness minerals, they do add a small amount of sodium to the water. For individuals on sodium-restricted diets or concerns about sodium levels in drinking water, alternative treatment methods like reverse osmosis or ion exchange filters can be used to target specific faucets for drinking water.

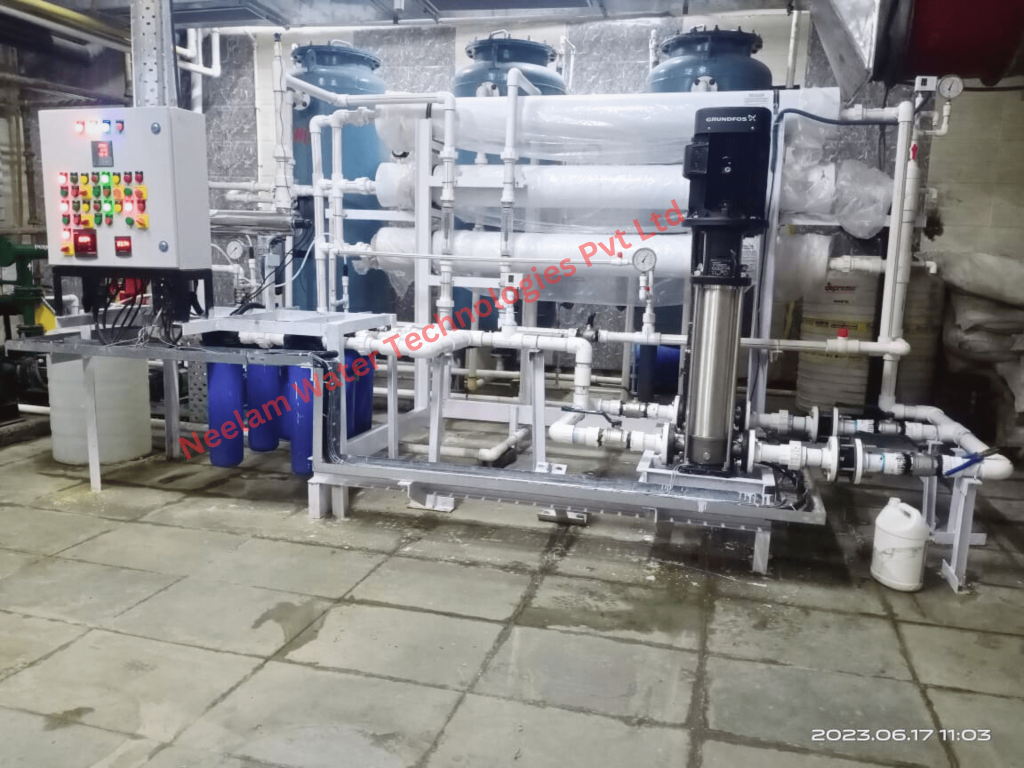

RO plant stands for Reverse Osmosis plant. It is a water treatment system that utilizes the process of reverse osmosis to remove dissolved solids, contaminants, and impurities from water. Reverse osmosis is a highly effective water purification technique that uses a semipermeable membrane to separate the water molecules from dissolved salts, minerals, and other contaminants.

The Main components of RO Plant Include:

Pre-Treatment System: Before water enters the reverse osmosis process, it undergoes pre-treatment to remove larger particles, sediment, chlorine, and other substances that could potentially damage the RO membranes. Pre-treatment may involve processes such as sediment filtration, activated carbon filtration, and disinfection.

Reverse Osmosis Membranes: The heart of an RO plant is the semipermeable membranes. These membranes have tiny pores that allow water molecules to pass through while blocking the majority of dissolved solids, salts, and contaminants. The membranes effectively remove a wide range of impurities, including bacteria, viruses, heavy metals, pesticides, and organic compounds.

Pressure Vessel and Pump: The reverse osmosis process requires high pressure to push the water through the membranes and facilitate the separation of pure water from concentrated brine. A pressure vessel and a pump are used to maintain the necessary pressure for optimal operation.

Concentrate Stream and Reject Management: As the water passes through the RO membranes, a portion of it becomes purified water, while the remaining portion contains concentrated contaminants. This concentrated stream, known as the reject or brine, needs to be properly managed or discharged.

Post-Treatment System: After passing through the membranes, the purified water often goes through post-treatment processes to further enhance its quality. This may include pH adjustment, remineralization, disinfection, and sometimes activated carbon filtration to remove any remaining taste and odor compounds.

RO Plants are widely use in application in industrial water purification, drinking water production, and wastewater recycling. They offer a highly efficient and reliable method for producing clean, purified water by removing a wide range of impurities, providing safe and high-quality water for various purposes.

An ultrafiltration (UF) plant is a water treatment system that employs the process of ultrafiltration to remove suspended solids, particulate matter, bacteria, and some viruses from water. Ultrafiltration is a membrane filtration process that uses a semipermeable membrane with fine pores to separate and retain particles and microorganisms while allowing water and dissolved solutes to pass through

Here’s an overview of the components and operation of an ultrafiltration plant:

Ultrafiltration plants are utilized in various applications, including drinking water treatment, industrial water purification, wastewater treatment, and process water recycling. They offer advantages such as high removal efficiency for particulates and microorganisms, low energy consumption compared to other membrane processes, and the ability to operate at lower pressures. Ultrafiltration provides a reliable and effective solution for producing clean and safe water by removing a wide range of contaminants, ensuring high-quality water for various purposes.

Welcome to DM (Deionization) Plant: Purifying Water to Perfection

At Neelam Water Technologies Pvt Ltd, we specialized in providing highly advance and reliable DM plant solutions for a wide range industries and applications. Our DM plant are designed to remove dissolved ions and impurities from water, delivering demineralized water of exceptional purity. Whether you require deionized water for power generation, pharmaceutical manufacturing, laboratory analysis, or any other critical process, our DM plant will meet your needs with precision and efficiency

Advanced Deionization Technology Our DM plant incorporates cutting-edge deionization technology to ensure the highest level of water purity. The process begins with the water passing through a cation exchange unit, where negatively charged resin beads selectively remove cations such as calcium, magnesium, sodium, and iron. The cations are exchanged with hydrogen ions (H+), leading to a significant reduction in mineral content.

Next, the water flows into an anion exchange unit, where positively charged resin beads effectively remove anions such as chloride, sulfate, nitrate, and bicarbonate. These anions are exchanged with hydroxide ions (OH-), further enhancing the water’s purity.

For applications that demand unparalleled water quality, we offer a mixed bed unit as a final polishing step. The mixed bed unit consists of a meticulously blended mixture of cation and anion exchange resins, working together to eliminate any remaining traces of ions. This ensures near-complete deionization and the production of demineralized water of exceptional purity, ready for the most demanding applications.

Reliable Performance, Robust Design Our DM plants are engineered to deliver reliable performance and long-term durability. We utilize high-quality cation and anion exchange resins that offer exceptional ion exchange capacity and longevity. The resin beds are carefully designed and properly sized to optimize ion exchange efficiency and minimize pressure drop, ensuring efficient and cost-effective operation.

To maintain the optimal performance of the DM plant, we offer comprehensive services, including periodic resin bed regeneration or replacement. Our team of experienced technicians can carry out these essential maintenance tasks to restore the ion exchange capacity of the resins, ensuring continuous and reliable operation.

Tailored Solutions for Your Needs At Neelam Water Technologies Pvt Ltd, we understand that each industry and application has unique requirements. That’s why we offer customized DM plant solutions to meet your specific needs. Our expert team will work closely with you to assess your water quality requirements, analyze your operational parameters, and design a DM plant that perfectly matches your needs. From small-scale systems to large industrial installations, we have the expertise to deliver reliable and efficient DM plants tailored to your specifications.

Choose Neelam Water Technologies Pvt Ltd for Superior DM Plant Solutions When it comes to achieving water purity, our DM plant solutions are second to none. With advanced technology, robust design, and personalized service, we are your trusted partner in providing demineralized water of the highest quality.

Contact us today to discuss your DM plant requirements and experience the excellence of our water treatment solutions. Together, we will purify water to perfection and ensure the success of your critical processes.

We made our system transparent and Client friendly by providing best services every time